Fx: 86-769-8531 3421

Monica: 86-13829137016

86-13925827222monicachao@xinkeju.com

Add: Dalang Town,Dongguan City,GD.CN.

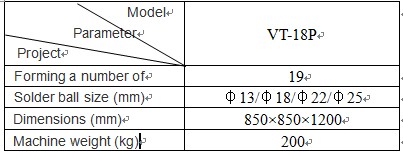

1.Technical parameters:

2. Description:

The pneumatic ball machine is a device for the production of solder balls have obtained national patent office issued a patent certificate, traditional production anode ball by hand pouring way, and can only produce a hemispherical, can not produce the entire spherical products. In casting the molten solder ball good tin tin pot into the water first, the hand holding a tin pot put a tin of water were poured into a hemispherical cavity mold inside, to be cured by hand the ball to be poured . This manual labor intensive production methods, production efficiency is low. Meanwhile, the use of manual operation, tin water temperature is high, the operation is easy to accidentally scalded, in operation there is a big security risk. Pneumatic ball machine is to overcome the above disadvantages of the prior art and the lack of a machine designed to reduce human labor intensity, while improving production efficiency, improve the working environment and to ensure production safety.

First pour water on molten tin good cover two V-shaped trough, tank tin hole flow of water along the inverted cone-shaped cavity in scoring, tin cavity filled with water, the remaining water and residual impurities tin in the V-shaped groove and cooled and solidified, the mold cavity to be spherical solder ball after cooling setting, the hand-pulled valve cover, cover is pulled, then pulled the active Template valve, two active template pulling the cylinder along the two guide rod slides outward simultaneously, the fixed template active template after separation of the mold cavity has solidified solder balls under the force of gravity will fall down, the chute fall finished box, to be solder ball after falling from the mold cavity, and then the two valve gate valve cover and the Active Template valve closed, repeat the next round of production.

3.Features:

1 mold made of high strength tool steel, to ensure that mold durable, tin smooth surface, small deformation.

2 high production efficiency: tin cooling rate is rapid, uniform cooling.

3 The machine is compact and easy maintenance.